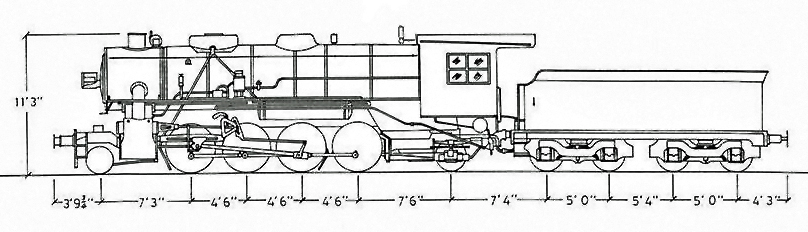

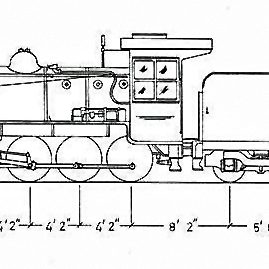

War in the Pacific caused unprecedented increases in traffic on Queensland Railways. This triggered a severe shortage of locomotives and rollingstock. In late 1941, Queensland appealed to the Commonwealth authorities for assistance with supplying the necessary items as part of the railway’s own workshops had given over to munitions work. When this request was refused, QR contacted an agent in U.S.A. to approach American manufacturers. The agent was supplied with specifications for a C17 type locomotive and, soon after, replied that a locomotive with a 2-8-2-wheel arrangement with similar power and weight was available. A meeting between Queensland Government officials and the Commonwealth Minister for Trade & Customs was arranged. (Large imports and payments to foreign countries needed Commonwealth Government approval). The price quoted had been £10,000 ($853,452.44 in today’s values) each but the meeting was told that it might be possible to obtain the engines under “lend lease” in which case the purchase price would not be payable and instead the items could be procured under a leasing arrangement. QR lost no time in placing an order for 60 engines on 29th January 1942. A major setback came in April 1942 when a cable from U.S.A. advised that the previously detailed engine was “now obsolete” and set out details of a standard light narrow-gauge engine that was now in production. This new design was slightly more powerful than the earlier model but also much heavier with the tender axles now supporting more than 10 tons each. The weight of the engine in working order was stated as 94.4 tons – much the same as the main line B18¼, yet the theoretical tractive effort of 20,130lbs (85%BP) was a little less than the C17. The biggest distress was that the length of the rigid wheel base had grown to 13’6” (4115mm) – one foot (305mm) longer than the accepted maximum on QR at that time. Design staff reviewed the plans and came to the conclusion that there was nothing in the arrangement that was wholly unacceptable but the engines would have to be restricted to main lines like the B18¼. The Commissioner for Railways initially tried to back out of the order due to the engines’ increased weight and consequent restriction to main lines, but ultimately said he would accept 20. They were the only ones of their type to come to Australia out of a total of 741 similar engines built for US Army Transportation Corps.

A dispute arose over the actual cost of the locomotives. The Commonwealth Treasury ruled that Queensland Government would have to purchase the engines. Total charges including ocean freight and insurance amounted to £445,384 ($34,876,444.79 in today’s values) or £22,269 ($1,743,822.24 in today’s values) per engine. QR expressed astonishment at this figure as Ipswich Workshops had recently constructed a B18¼ engine for £12,267 ($960,585.36 in today’s values). The argument continued for a long time before a compromise was finally reached well after the engines had been delivered. The Commonwealth agreed to only charge Queensland £345,000 ($27,015,729.01 in today’s values) or £17,250 ($1,350,786.45 in today’s values) per engine and bear the balance of the cost themselves. This was no victory for Queensland as they were under the impression from the original discussions in January 1942, they might only have to lease the engines and not purchase them outright. Additionally, the negotiated price was still much dearer than a more powerful B18¼.

Baldwin Locomotive Works of Philadelphia constructed all twenty engines and they were delivered in 1943. The locomotives carried that Company’s builder numbers 69451 – 69470 and had been issued road numbers 216 – 235. The first batch of five arrived in Sydney by sea in May 1943. They were railed to Clapham for transhipping and on forwarding to Ipswich Workshops. N°223 was the first engine to enter traffic on 26th June 1943. Within five months all had been delivered with the last, N°235, entering service on 18th November 1943.

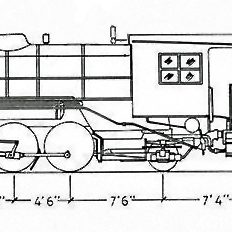

N°224 did a successful trail run from Brisbane to Toowoomba and return with a full B17 load on 7th July 1943. Unfortunately, the axleboxes on several of the engines began to develop serious wear within a few weeks. On 11th September 1942, N°229A had its wheels pressed in on their axles to the standard QR distance of 39” (991mm). While at Ipswich Workshops, the opportunity was also taken to turn the tyres to the standard QR cylindrical profile. In the course of this work, it was also decided to provide thinner flanges on the inner (2nd & 3rd) coupled wheels. Oilers were also fitted to lubricate the slog faces. These alterations produced the desired results and similar work was commenced on other engines. Ultimately all engines were fitted with standard QR type axle boxes. The original tenders rode poorly and were subject to a number of derailments. After investigations, some adjustments were made but these did not solve the problem. So, for the sake of safety, a speed limit of 30mph (48kph) was imposed on the class and they were prohibited from hauling passenger trains.

With sixteen-inch diameter cylinders and eight coupled wheels they should have been classified C16 but to distinguish them from that existing class they were called American C16 i.e., AC16. The U.S. Army Road numbers also presented a similar problem as there were several engines already in service carrying numbers in the 216 – 235 range. A simple expediency was used to overcome this issue; the letter “A” was added after the number of the new American engines to differentiate them from engines with the same numbers that were already in service. When the engines arrived, they had USA painted on the tender sides in large white lettering. Apparently, this caused irritation in some circles and Railways’ Minister Larcombe directed it be obliterated immediately.

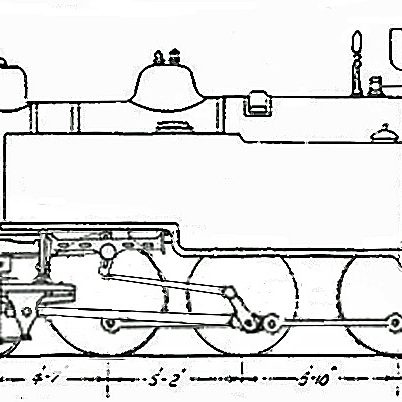

There were mixed feelings about the class. The AAR Master Mechanic’s smokebox was a novelty in the eyes of local railwaymen. Its self-cleaning arrangement was so efficient that it was found that any residue only required cleaning out when the boiler was being washed out. The headlight mounted on the smokebox door proved to have advantages and was later adopted for some other classes. Another feature that proved popular was the use of louvre coal boards and these were subsequently fitted to all QR steam engines. Many appliances that were considered standard equipment on locally built engines were missing from the imports. There was only one gauge glass to register the boiler water level; there were no snifting or pressure relief valves on the cylinders and no hand brake. The floor level shovelling plate on the original tenders was unpopular and made the fireman’s work more difficult. Although the boiler steamed freely, the firehole door was disliked as was the low cab roof. There were numerous complaints about the original ‘banshee’ whistles being too noisy and these were eventually replaced with the standard three chime whistle similar to those fitted to the BB18¼ Class. Arrangements were eventually made to fit the additional gauge glass, snifting valves and tender handbrake but surprisingly no pressure relief valves. The engines were fitted with guard irons, but amazingly these were never replaced with cow catchers which were normal fixtures for all QR locomotives except tank engines.

Many members of the class spent lengthy periods out of service in the early 1950s. This was during the years when workshops were struggling to overcome arrears of maintenance and AC16 engines, being the least powerful of the main line fleet, received low priority. Numerous modifications were carried out to the engines during their lifetime. The most notable of these was fitting of replacement tenders. In 1958, N°217A was fitted with a C16 type tender taken from a withdrawn locomotive allowing the previously imposed speed restrictions and prohibition on working passenger trains to be lifted. All 19 members of the class then remaining in service were similarly treated. After being fitted with these tenders, seven of the class were attached to Alpha where they had a brief period of glory in the early 1960’s when they replaced the C17 Class hauling the air-conditioned “Midlander” between Alpha and Winton. The American engines with a larger boiler capacity were able to reduce running times in the sections that contained many long banks. 60-ton Diesel Electric Locomotives took over the working in 1963.

N° 225A was the first engine to be written off in October 1957 as a result of accident damage. By 1964, time was starting to run out for steam. Two AC16s were written off in that year and another three during the following year. Their numbers had been reduced to eleven by the end of 1966. Those remaining in use were based at Ipswich, Rockhampton and Toowoomba. Five were withdrawn in 1967 and the same number in the following year. The last AC16 in service was N°218A at Rockhampton and it was set aside in June 1969.

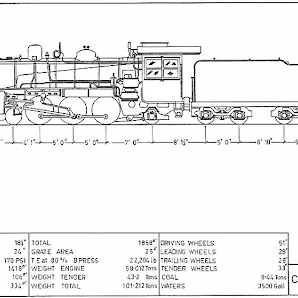

Locomotives

-

Wheel arrangement

2-8-2

-

Cylinders (diameter X stroke) ins. (4)

16 X 24

-

Rigid Wheel Base

13’6”

-

Length over Buffers

62’11” (53’3½” with C16 Tender)

-

Coupled Wheels diameter ins.

48

-

height_over_chimney

11’3”

-

Axle Load

10.2 (9.2 with C16 Tender)

-

Boiler Pressure psi

185

-

Heating Surface of tubes - sq feet

1371

-

Heating Surface total - sq feet

1745

-

Grate area - sq feet

27.7

-

Weight - adhesive - tons

37.0

-

Weight Engine

53.4

-

Coal capacity - tons

6.5 (8 with C16 Tender)

-

Tractive Effort - lbs. (85%)

20128

-

Factor of Adhesion

4.12

-

Valve Gear

Walschaert

-

WH Pump

9½” X 9½”

-

Brake Valve

6-ET